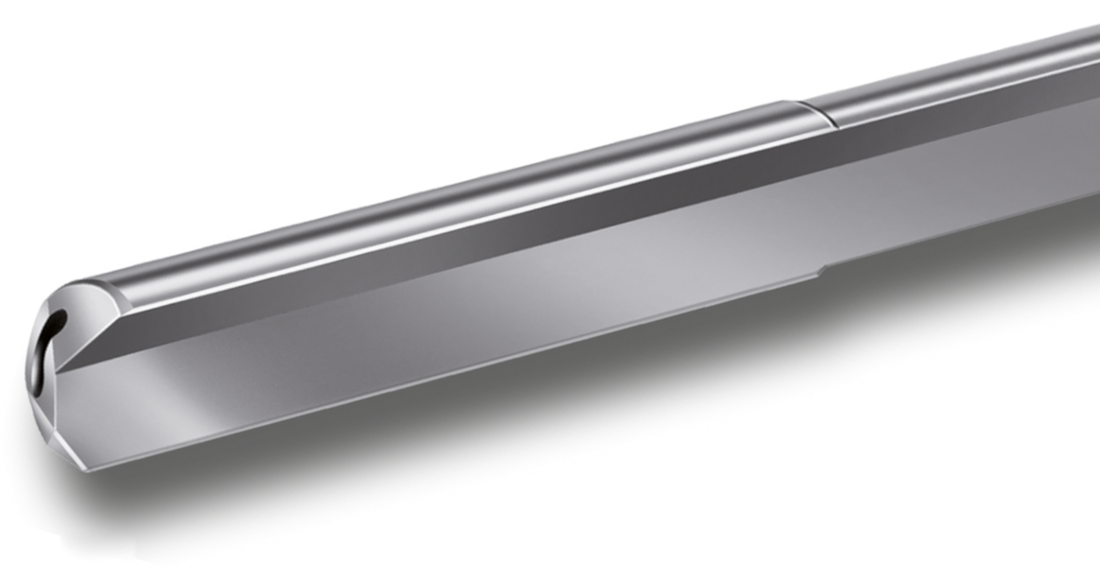

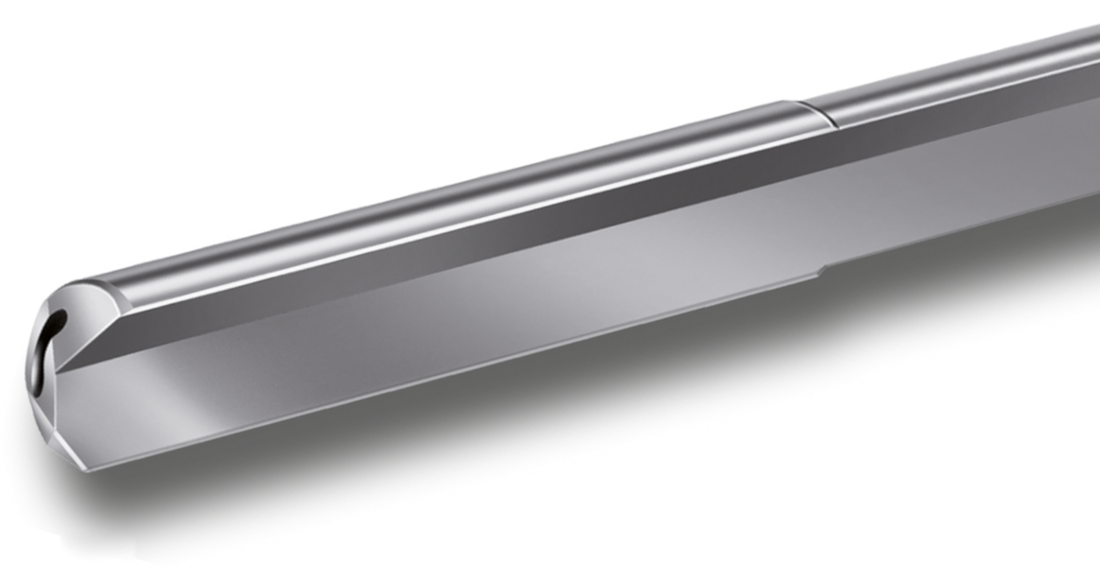

Gun drilling process is used to produce deep and straight holes. This process is very specialised as compared to the conventional twist drilling process. The standard gun drill tool geometry has a single effective cutting edge. Unlike the twist drill the gun drill cuts through the metal eccentrically and once inside the component the tool self-pilots itself. The hole is further burnished due to the guide pads which finally results in a precise round hole with maintained straightness. The Coolant enters the tool through the coolant through hole and the chips are gushed out through the V shaped profile on the gun drill. Gun Drilling is effective from ф1 to ф30, but if you wish to go higher, BTA drilling becomes more effective than gun drilling.

Gundrilling, one of the basic and frequently performed material removal processes in the automotive, die and mold, and turbine industries, is becoming increasingly more complex, demanding, and experiences an unprecedented growth. Inspite of significant increase in the demand for economically producing holes and forprocess reliability, gundrilling and gundrill manufacture are still considered an esotericart, and there still exists a lackof knowledge on the exact relationships between the point geometry, the grinding process parameters, and the process mechanics, resulting inmany methods for drill production and, consequently, in wide variations in process performance.

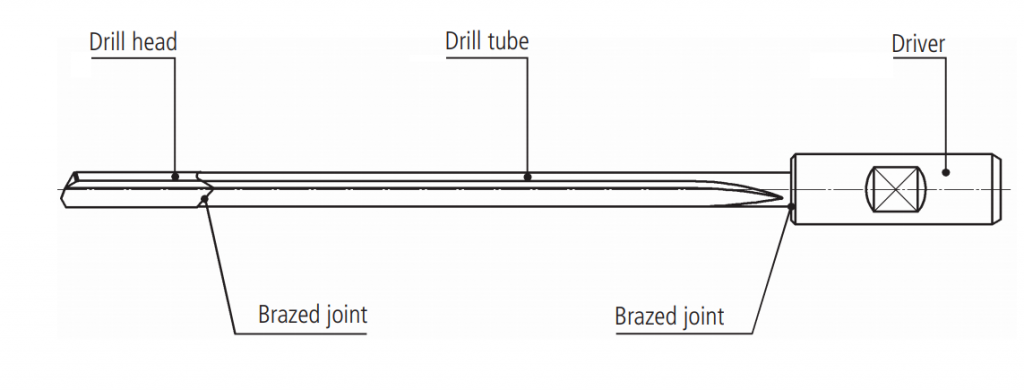

Single Flute Gundrills consist of a carbide tip, a heat treated alloy shank, and a steel driver, typically silver brazed together into one precision unit.

Tip: The tip is the most critical element. The tip cuts the hole as it pilots the drill through the work piece, producing precision holes in a single pass. The drill’s point, or nose grind, has two basic angles that may be varied for optimum results depending upon the material being drilled. These angles balance cutting forces, distributing them to the tip’s bearing pads to keep the drill concentric. The tip is slightly larger than the shank, so the shank can rotate freely without contacting the hole wall. A round, kidney-shaped, one bigger hole or two round smaller holes through the tip line up with the shank’s channel to allow the flow of coolant at high pressures.

Shank: The shank is made from aircraft grade alloy steel tubing with a110° -120° Vee-flute formed to the center of the shank’s diameter. Coolant is forced from the driver through the center of the shank to the tip, where it is flushed back along the shank’s flute. The shank maintains proper gundrill alignment and must be strong enough to absorb cutting torque and thrust. If the shank is too stiff it may transfer minor mis-alignment in the machine to the tip, but it must not be flexible enough to sag or whip at high RPMs. Driver: Drivers are cylindrical, with an undercut or flat section for the set screw, which holds in the spindle bore. They are manufactured to industry standards or to special diameters and a concentric hole through the driver’s length allow coolant to pass through to the shank and tip.

Solid Carbide Single Flute Gundrills are manufactured as a single piece of carbide, replacing the tip and tubes braze section resulting in an extremely strong, ridged tool. Most small diameter drills significantly benefit from solid carbide drills because they yield the maximum allowable surface footage and feed rates with decreased whip factor do the their rigidity. Solid carbide drills are manufactured through a new process using modern CNC equipment resulting in high quality and faster lead times.

Two Flute Gundrills are used in non-ferrous materials and allow for up to 80% increase in feed rates. Special nose configurations are designed and must be exactly duplicated to obtain repeatability. When using this type of drill the increased feed rates require more coolant pressure to evacuate the chips. The rule of thumb is 20% – 30% more coolant and pressure than the required single flute specifications.

Interlocking detachable heads allow you to install a new head in minutes without removing the shaft from the assembly. Benefits include no down time, increased tool life and greater productivity. Order them to fit your existing drivers, shanks, and detachable heads. If your standard shanks are in good condition, you can convert to this system.

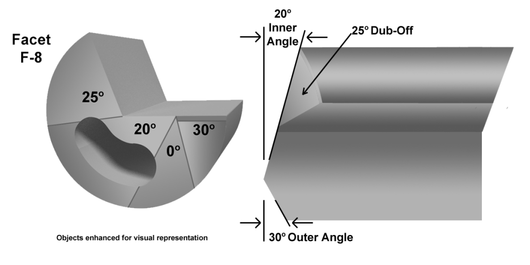

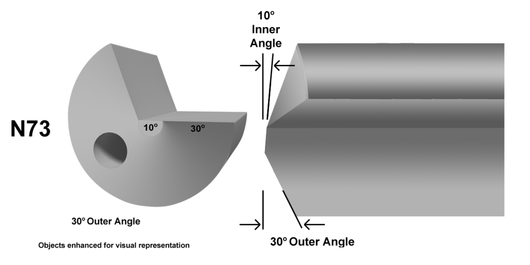

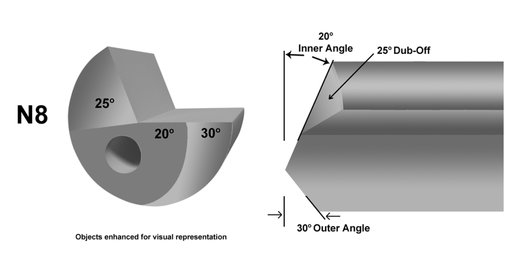

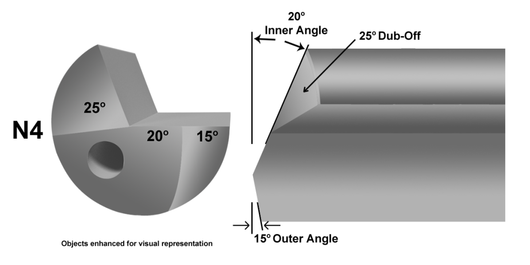

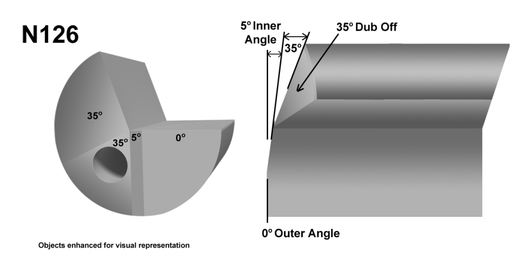

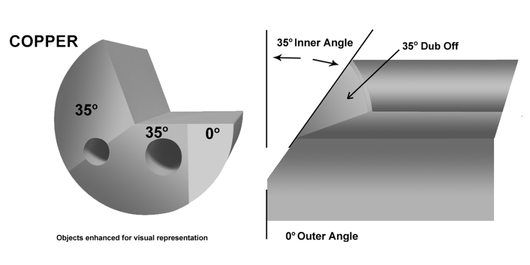

There are numerous nose grinds that have been established by end users to critique applications. There are a handful of standard general purpose grinds which are industry standard and have good success for a given material. Modifications are made to these due to material hardness, softness, tinsel strengths, lack of coolant pressure or lubricity, etc.

The N-8, N-4, N-73, and Facet grinds are Industry Standard Grinds while bottom forming, corner radius, full spherical radius, and flat bottom may also be produced in a single pass. All of which can be reproduced on our deep hole drilling resharpening machine, with a specific sharpening fixture and applicable diamond wheel.

The center design of gundrills allows for a wide range of Nose Grinds from a full spherical radius to a flat bottom design. The Nose Grind angles are important in achieving optimal results. Angles can be modified to improve the flushing action of the high pressure oil and to improve chip control and removal. Specific grinds have been developed for severe applications such as exit breakouts and interrupted or angular entries. Some of the most popular Nose Grind configurations are shown here.

Facet grinds are preferred on specific applications or when regrind fixtures limit the cam type sharpenings. They can be ground to various slash type angles with good performance, and they allow a greater amount of clearance for coolant to cool the chip at the cutting edge. This F8 grind is standard on most European applications.

This Nose Grind is used for drilling stacked parts and angular entries. Due to the point’s placement near the center of the drill, this is the strongest gundrill.

General purpose stock drill grind for steel, inconel and stainless steel.

This Nose grind is most used in gun drilling of aluminium and brass.

This Nose Grind is for applications requiring nearly flat bottoms. It can also be ground for a completely flat bottom or on difficult materials used to qualify bottoms only.

This Nose Grind is for applications requiring nearly flat bottoms. It can also be ground for a completely flat bottom or on difficult materials used to qualify bottoms only.

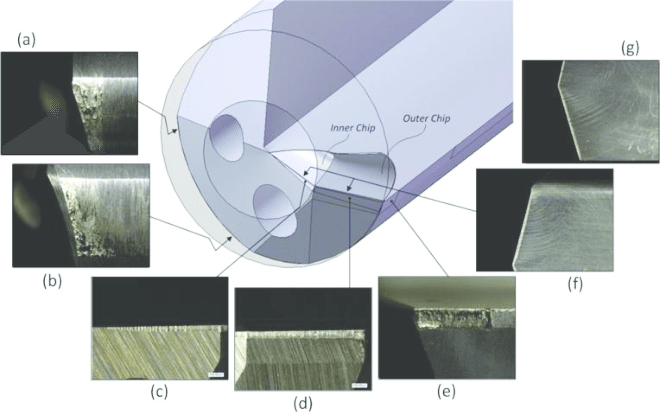

Straightness control in deep hole gundrilling of is challenging. The drills are found to degrade rapidly on the cutting edges, bearing pads and side margins, largely due to the extreme heat resistivity of the high temperature superalloys. Severe adhesive wear developed on the rake and flank faces deteriorates cutting efficiencies of the cutting edges while diffusive wear on the bearing pads and side margins deteriorates self-piloting efficacies of the drill. Coupled with highly irregular wear rates on the inner and outer cutting edges, the drills are forced against the hole at high rotational speeds – leading to escalations in frictional contact, heating and thermal damage on the bearing pads and side margins. As a consequence, the drills are deflected from the designated drilling course and resulted in straightness deviation on the part of hole drilled. Through the accumulation of partial straightness deviation over the course of high aspect ratio drilling, the final hole produced is deflected in a constant trend as governed by the rate and behaviour of tool degradation.