SRB - Skiving Roller Burnishing

Skiving Roller Burnishing machine is also called boring rolling machine, scraping rolling machine, cylinder scraping rolling machine, etc.

Skiving is a hole finishing process used when very tight dimensional and geometrical tolerances are required. It is the fastest method to achieve surface finish having very fine peaks and valleys ideal for roller burnishing process. The Skiving Tool is basically a twin/multiple edge floating reamer which follows the existing bore. The Roller burnishing tool coldworks the surface by merging peaks & valleys thereby producing very high surface finish and also a hardened surface. Both Skiving and Roller burnishing processes can be done simultaneously by using combined Skiving Roller Burnishing Tool. This process is 8 – 20 times faster than honing operation. The Skiving blades and burnishing rollers are expanded hydraulically while rotating and feeding though the bore. At the end of the operation these are retracted and the tool is withdrawn. High pressure coolant is supplied to the tool through the annular area between the bore and the tube outer diameter. The coolant along with the chips is evacuated from the other side. Compared with the old boring + rolling or boring + honing, the processing time can be saved by 80-90%.

Profimach offers dedicated Skiving & Burnishing machines for high production scenarios. This setup can be accommodated in a BTA drilling machine.

Skive Burnishing Tool Operation

Rounder. Smoother. Faster.

Skiving operation:

Two thin chips are cut at a high feed rate of 1-4 mm/rev while the tool passes through the workpiece. This cutting operation determines the finished diameter and tolerance of the cylinder. Surface finish Ra= 4-10 μm (skiving).

Roller burnishing operation:

Roller burnishing is performed on the return stroke to have the best surface quality but can also be done during the boring/skiving operation. The plastic deformation taking place provides a surface finish of Ra= 0.05-0.20 μm – better than broaching, grinding or even honing. Localized surface hardness is increased by approximately 50% (steel).

Advantages of the skiving /scraping roller burnishing machine tool

The processing speed of the skiving roller burnishing machine tool is ten to twenty times that of the honing machine tool, and it has low noise and no pollution, which can save the processing cost and improve the processing efficiency.

Processing methods of SRB

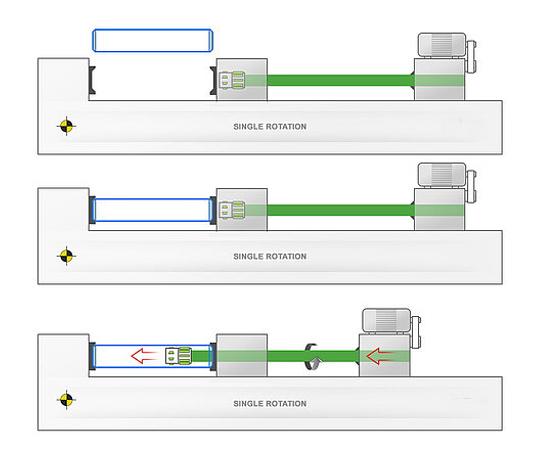

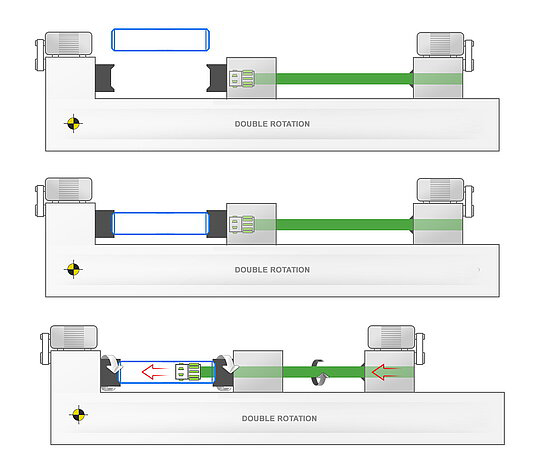

Single-turn processing method and double turn processing method

Single-turn processing method - Single rotation proces: the workpiece is fixed, and the tool rotates and feeds.

Double-turn processing method - Double Rotation proces: the workpiece is rotating and the tool rotates in the different direction and feeds.

Roller burnishing tools

Roller burnishing tools

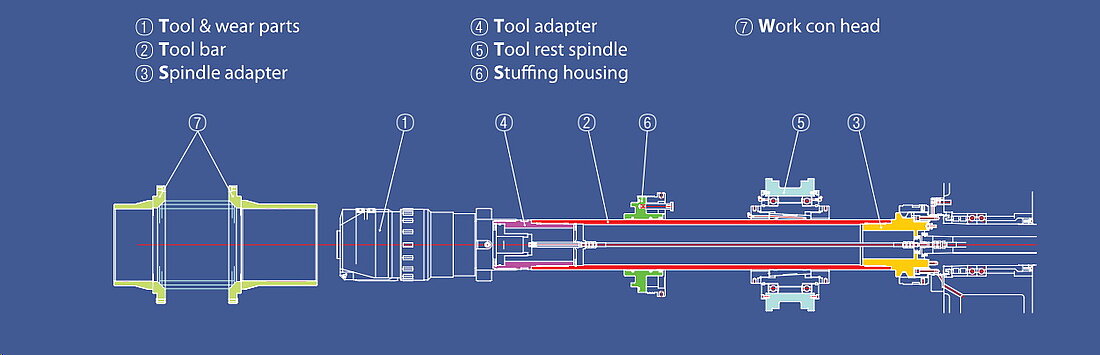

The combined skive burnishing tool can process cylindrical tubes and other workpieces in a short time, and can be processed in one operation.

Since the scraping and rolling can only work in one direction, the cutting and rolling process is completed in one operation.

Using a machine-determined conversion system, the tool can be quickly rolled back without compromising the finished scraping surface.

Product advantages:

● Surface quality reached Rz<1um

● Extremely high dimensional stability with tolerance class IT8.

● Assembly surface processing is safe and fast and low cost.

● The surface is harder and more wear-resistant after rolling.

● Non-cutting, low noise

Product description:

● Processing

● Diameter:60-440mm

● Scraping speed:2-3m/min

● Max. machining allowance:1mm

● Feed rate:3-6mm/r

Reachable precision and performance Summary of performance

Skiving

• Surface finish Ra= 4-10 μm, Rt= 20-60 μm, at normal feeds (1-6 mm/rev) and a speed of vc: 150-300 m/min.

• Lower feeds improve the surface finish.

• The skiving tool determines the finished diameter and produces a very accurate finish from entrance to exit. On thin-walled tubes, elastic deformation from clamping and machining will influence the finished diameter.

• The skiving tool follows the inner diameter (ID) of the component which secures the straightness.

Roller Burnishing

• Surface finish Ra= 0.05-0.20 μm.

• If the tube is very thin-walled, the burnishing will not be as effective as for normal tubes with t/ID = 0.1. (Where t is wall thickness).

• The tolerance grade is IT8 or better. Strong clamping, crossholes or irregular tube shape can deform the tube in different ways. Uneven wall thickness can cause ovality.

• The surface hardness can be typically increased by up to 50%.

• Finish can be better than grinding or honing (but lacks oil retention).