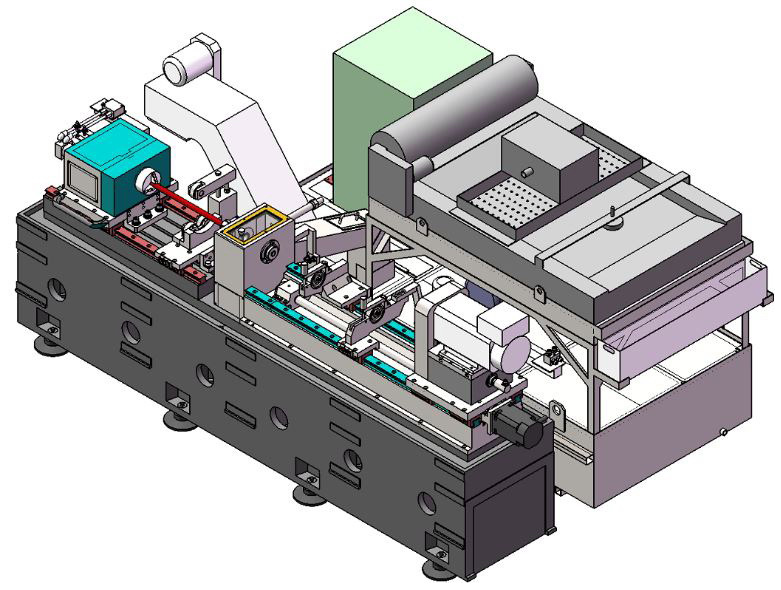

• PDHG-10-MH-Series: deephole drilling machine (max hole diameter is 10mm) -MH = Micro Hole

• PDHG-20-Series: deep hole drilling machine (max hole diameter is 20mm).

• PDHG-30-Series: deep hole drilling machine (max hole diameter is 30mm).

• PDHG-40-Series: deep hole drilling machine (max hole diameter is 40mm).

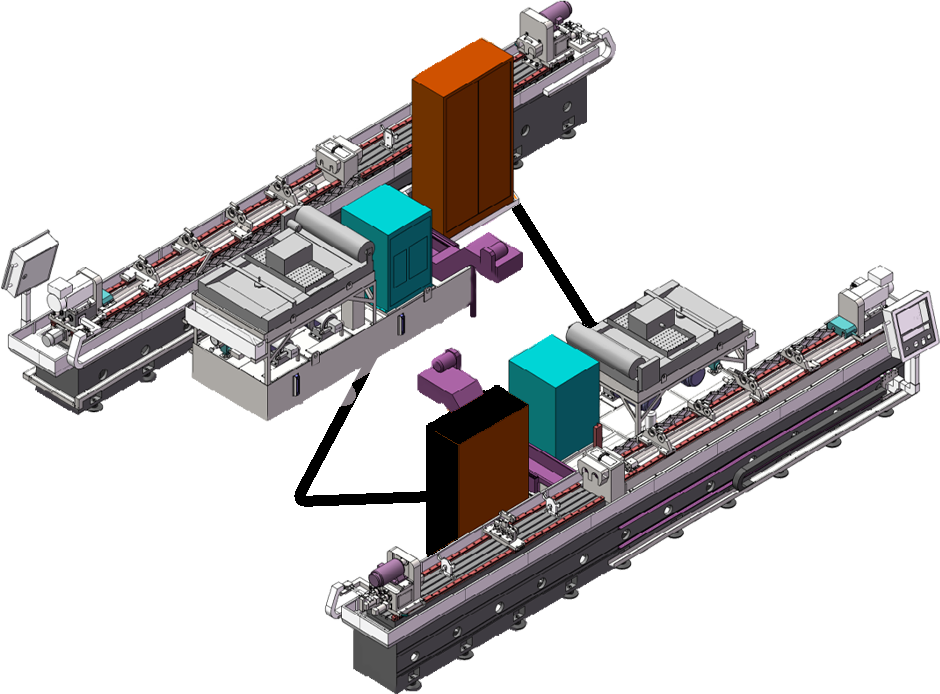

• Single spindle gun drilling machines

• Double spindle gun drilling machines

• Four spindle gun drilling machines

• Six spindle gun drilling machines

• Solid drilling 1.5mm to 40mm

• Can drill/bore the depth up to 4.000mm. (depends on different models).

• Length to diameter ratio reachable 100:1 (depends tooling and material)

• If both tools and job rotate, the deviation is 0.5mm per 1000mm.

• If only gun drill or job rotate, the deviation is 1mm per 1000mm.

• Solid drilling: IT9-IT11. hole roughness: Ra3.2um-Ra6.3um.

If you have specific requirements, much better surface roughness will be avaialble by using special tools and drilling solution. Ask for outr support.

through hole, blind hole, concentric hole, eccentric hole, step hole.

Automation:automatic loading and unloading feeding system is optional.

CNC controller: Siemens/Fanuc/GSK CNC /PLC controller.

• Cart

• Air conditioner for electrical box

• Coolant pump

• Steady rest for tools

• Working light

• Tool box

• English operation manual.

• Auto chips conveyor

• Drum type paper filter

• Guide bush

• Steady rest guide bush

• Oil centrifugal extractor

• Transformer

• Coolant chiller

• Full cover safety guard.

• Molds industry: water hole of molds, Thimble hole, runner hole, guide post hole and bottle mold hole.

• Hydraulic industry: hydraulic cylinder, servo hydraulic cylinder, industry cylinder, piston, oil hole of hydraulic valve block.

• Automobile industry: cylinder head, cylinder block (internal combustion engine), crankshaft, steering gear rack, gear shaft and valve core.

• Roll industry: Metallurgical roll, corrugated rod of paper industry.

• Oil pump nozzle industry: injection gas, needle valve body, plunger sleeve and other parts.

• Textile machinery industry: all kinds of spindle center hole, eccentric hole processing, etc.

• Medical equipment industry: titanium alloy, stainless steel 316 (titanium alloy) bone needle and other shaft .

• Military industry: test torpedo launch tube, antimissile launch tube, high-speed oil cylinder, reentry machine parts, etc.

• Coal industry: hydraulic cylinder products, etc.

These machines are built to manufacture high precision parts and can be customized to suite high volume requirements. These machines provide excellent straightness, surface finish and bore tolerance. Length to diameter ratios of up to 125 is possible.

• Component counter Rotation to ensure excellent straightness

• Use of ball screw and servo drives for linear motion.

• Multiple tool steadies to provide tube support.

• Rotating cone / Self centering chuck for part clamping.

• High pressure coolant filtration system

• Oil chilling and automatic lubrication.

• Fanuc/Mitsubishi-Syntec / Siemens PLC or CNC controls with touch screen HMI.

• Integrated design to reduce overall machine footprint.

The bed consists of high resistance and stiff rectangular sections, appropriately ribbed with two high precision and high rigid Linear guide ways that are opportunely sized for maximum rigidity. To ensure that the optimum rigidity and stiffness in the machine bed is guaranteed, the latest CAE techniques are used to determine the optimum design of the bed structure. Supplementary the machine bed is optimized by using advanced FEA software for thermal stability, vibration resistance and improved accuracy. Oversized dimensioned, heavily ribbed structure which is fixed to the floor over its entire length with different support and leveling points, allowing a rigid fixing to the foundation.

Stress released high quality Cast iron made, the infinity variable feeds are granted through A.C. Brushless motors controlled by its electronic digital drives. The transmission is obtained with pinions engaged on a helical-toothed rack fixed in the center of the bed, with a special drive that permits the compensation of the thrust forces and moves backlash-free or by an oversized high precision Balscrew with high torque motor.

Carriage guides have antifriction material (TURCITE) for a precise and accurate movement to avoid any stick-slip problems even at low feed speeds. Taper gibs provides precise adjusting of carriage geometry. The guides lubrication of the carriage is automatic and centralized lubrication control provides trough autonomous electropump and tank. There is an electric oil level signal to control whenever there is a lost of oil and gives directly the message to the CNC.

In order to optimize any resistance the drive is duly dimensioned with big torque and low inertia, in order to achieve high acceleration. Scrapers grant the fine and good cleaning of the guideways’ surface.

To control and save the pieces and tools there is a carriage movement overload protection that is electronically made directly on the digital motor drive, that, during machining when the tool force comes to limit is working as follows:

• Feed stop of boring carriage

• Automatic backward motion of boring head from about mm. 20 (opt)

• Spindle stop

• Pumping station stop

The head, casting made, mounted on the boring carriage, is of a box double walled structure, appropriately dimensioned with suitable ribs. It offers maximum rigidity and ensures chatter free operations, also during the most severe working conditions.

Some of the main features of our machine spindle/boring head are as follows:

• The well ribbed headstock ensures maximum heat dissipation.

• Thick cast iron casing absorbs cutting vibrations

• Large angular thrust bearings for heavy duty boring operations

• Roller bearings with large bearing areas for increased spindle rigidity.

• P4 class front roller bearing ensures smooth even turning and has high radial load capabilities.

• To increase spindle stiffness and ensure longer spindle life the spindle shaft is surface hardened at the bearing contact points before the final grinding process. This provides a tough inner core to absorb the cutting forces while the hardened areas at the loading points prevent rapid wear on the spindleshaft, thus producing a long lived spindle.

• The latest computer analysis techniques are used for bearing arrangement on the spindle shaft to ensure optimum stability in the spindle structure.

• Thick Meehanite cast housing absorbs and dampens cutting vibrations.

• Well ribbed housing quickly dissipates heat from bearings and improves cutting accuracy.

• To optimise headstock design, computer simulations and dynamic analysis are performed to better understand the stress applied to the headstock during heavy cutting.

• After headstock assembly, each spindle undergoes running tests for 8 - 24 hours to ensure bearing temperature is not excessive.

The speed-change gear box can be manual or hydraulically/servo controlled, and the shifting is confirmed by means of light indicators. The speed-change can be directly carried out through functions "M" or, in case the machine is manually operated, by the appropriate switch on the control panel.

By the control unit, the spindle speed values are directly programmed in R.P.M. The lubrication of all power transmission parts is ensured by a forced circulation unit, which supplies the oil mist to all mechanism in movement and is controlled by a flowswitch.

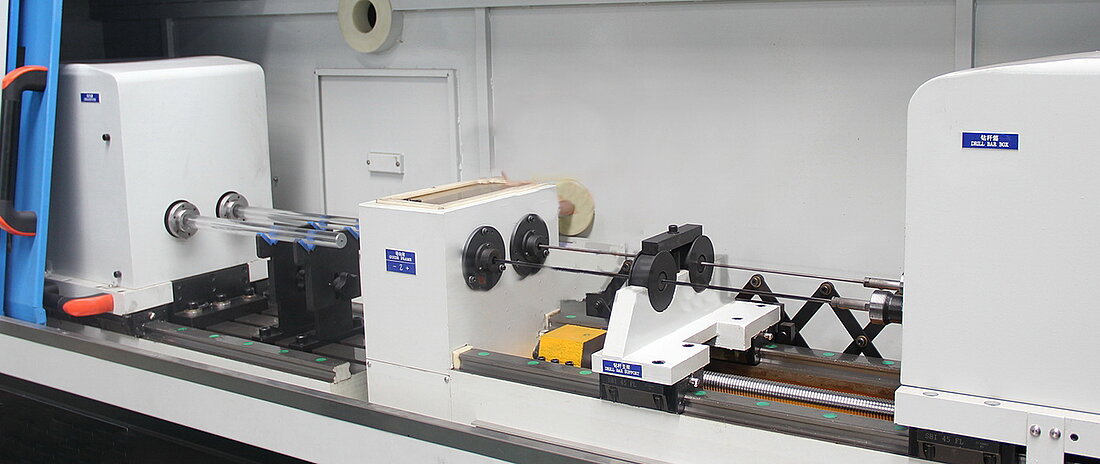

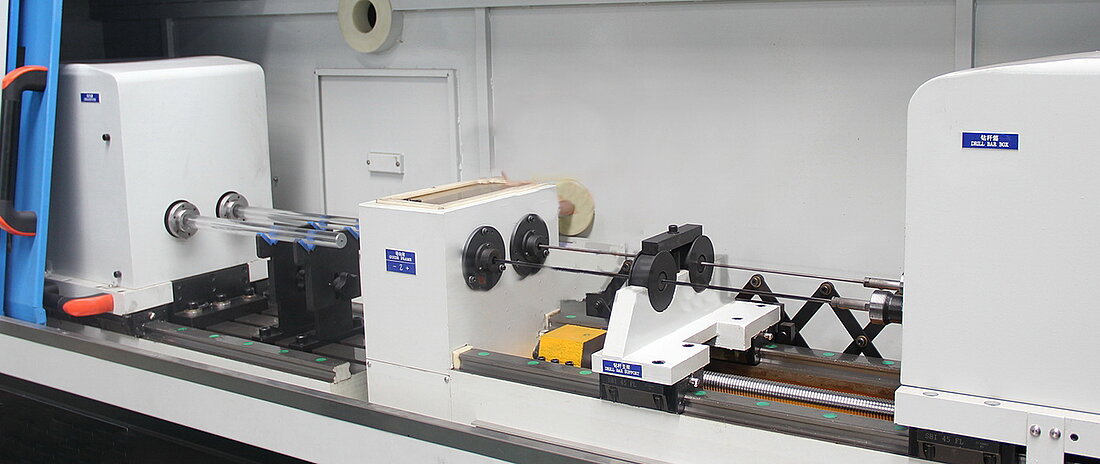

Vibration Dampeners

Vibration dampeners allow rotating drills to be guided while dampening vibrations, resulting in a better finish and predictable tool life.

Vibration Dampener Carriage

A vibration dampener carriage is mounted onto the tracks of the machine and securely hold components to dampen vibrations in the dril. These are engineered for strength and manufactured out of cast iron. The number of dampeners required is based on an engineering analysis of hole depth.

Vibration Dampener Collets (optional)

Collets are made from a special dampening material that does not damage drill tube surface. These are mounted in vibration dampener cartridges and fit snugly around each size of drill tube.

All slideways and moving members are automatically lubricated. Lubrication channels are milled into the underside of the carriageway and turret to allow oil to be constantly forced between the moving members for added machine life.

The lubricant is controlled through pressured system that monitors the amount of oil in circulation. Any leaks or pressure drop will be detected immediately and result in an alarm being displayed on the controller. Excess oil from the Z-axis slide ways is caught by a ledge cast into machine bed which is collected in a sump at rear of the machine. This keeps the coolant form being excessively contaminated by lubrication oil.

COOLANT/FLUSHING SYSTEM

Chip conveyor and primary coolant collector

Magnetic separator

Coolant System

Coolant system options, such as refridgerant chillers, oil-water heat exchangers, and oil-air heat exchangers, help maintain the accuracy of the process and the durability of the machine by removing heat from the cutting fluid.

Pumping units

Coolant tank with pumps and filters