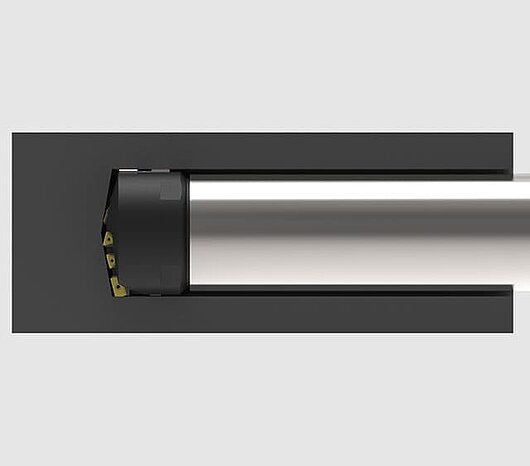

Trepanning Process

Trepanning is a special operation mainly used on when conventional machines are tooled up to do deep hole drilling. Usually in such cases the machine power is less and hence Solid BTA drilling is not possible. Trepanning is also used when a solid core is required. The trepanning operation is performed on a blank workpiece without any holes. The Tool geometry allows cutting only on the circular section whereas a solid core is left in the middle. This core can later be extracted for use. Typically only through hole applications are advisable with Trepanning since the core extraction can become troublesome in case of a blind hole. The tool covers a large range of diameters upto 500mm. There are limitations to the lower level of diameter that can be achieved with this process due to the geometry of the tool.

Our BTA drilling machines can handle all trepanning jobs

Increase your productivity and reduce your costs

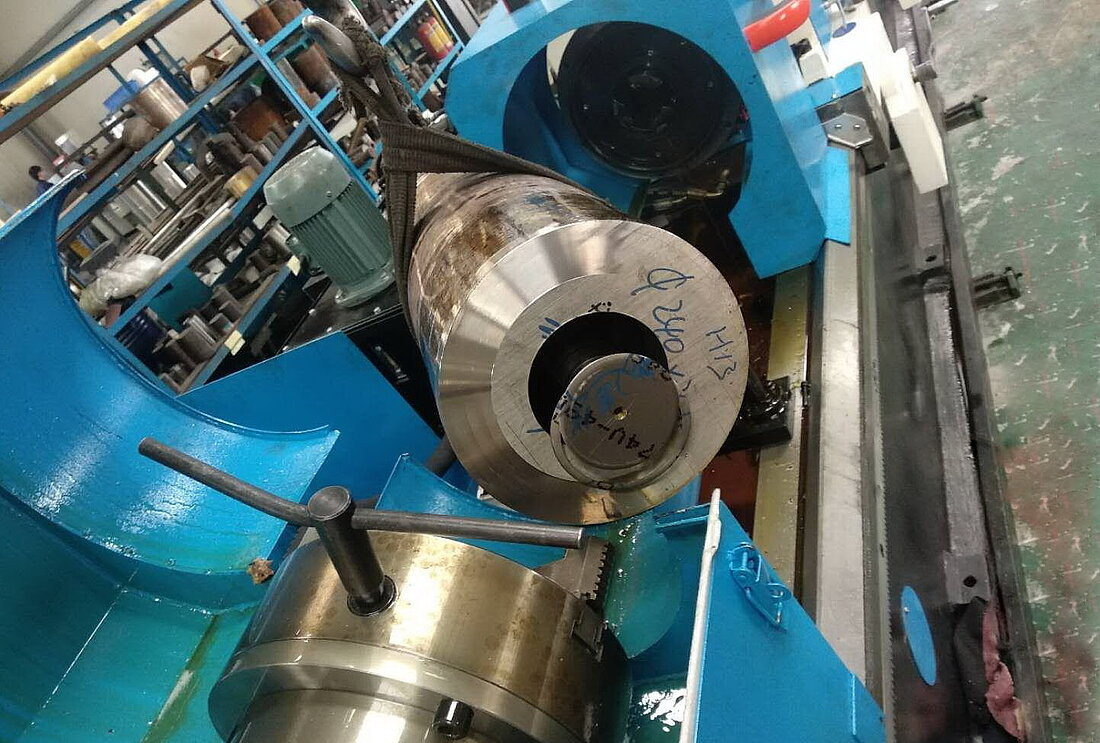

Sample of Trepanning on our BTA machines

Trepanning tool:

● OD 240mm

● ID 195 mm

Part diameter:

560mm

TREPPANING JOB DONE