The industries where Profimach® deep hole machining technology matters most are those where the competing demands for the highest-quality parts and lowest cost per part are most critical. And while these texts focus on the industries where Profimach® deep hole technology and expertise contribute the most to your success, it is by no means a complete listing. If, after you’ve reviewed the following pages, you have questions regarding other industries and applications; contact your profimach® representative to review solutions that match your specific production needs.

Profimach is the partner of choice to discerning customers across a wide range of industry segments. We enable mold and die production for electronic components, automotive, information and communications technologies, and home appliances. In parts production, we strengthen aerospace and aeronautics, automotive and motorsports, medical technology and watches and jewelry.

Medical implants such as bone nails, medullary nails, bone screws, or stents, most of which are made of titanium or stainless steel alloys, require maximum-precision deep hole drilling with minimum runout. Parts with very thin walls are exactly those that present a real challenge, but that can also be brilliantly and reliably overcome with Profimach deep hole drilling machines. Profidrill’s Medical implant solutions include various features that allow precise drilling in material like Titanium and Stainless Steel which are frequently used in these applications.

Whether it's drill collars, drillpipes, or submersible pumps – profimach deep hole drilling machines will allow high-precision drilling operations with minimal runout in alloys typical for the application such as nickel steels, and come with additional features specially developed for the task; for example, chip breakage monitoring for reliable cutting which is integrated as standard. Profridrill's solutions for Oil & Gas are perfectly tuned to optimize drilling on exotic materials like Stainless Steel, Duplex and Inconel used in that Industry. Machine specs and design are customized to suit the needs of the application on a project to project basis.

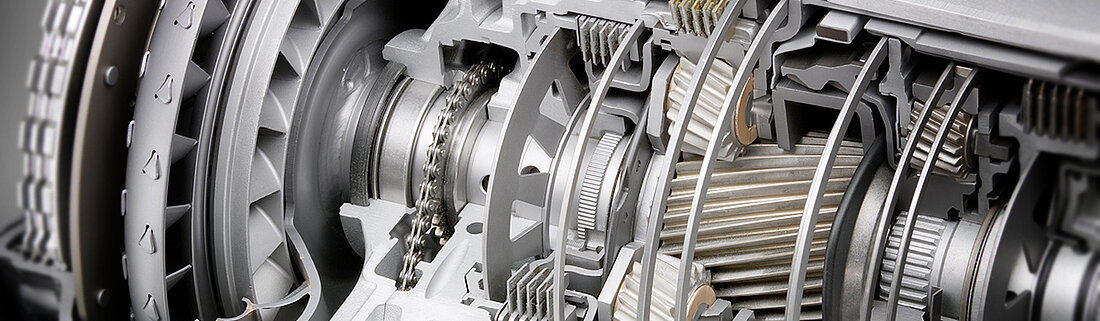

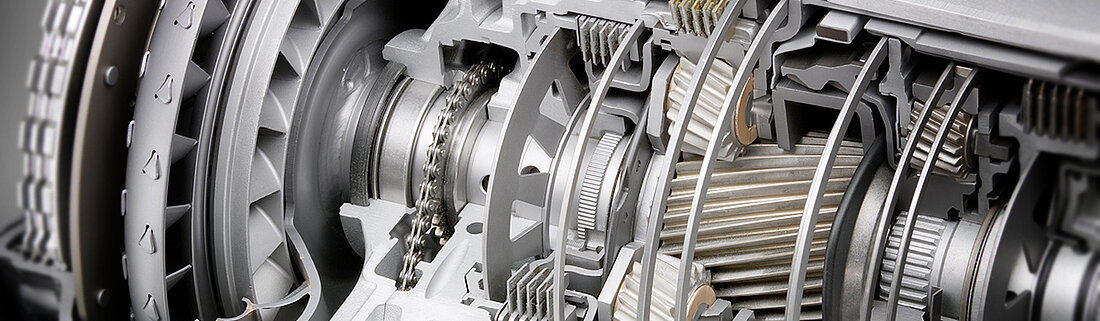

Camshafts, crankshafts, transmission shafts, drive shafts, flanged shafts, injection nozzle bodies, fuel rails, valves, con-rods, or piston pins – there's hardly any other industry in which so many deep hole drilling applications are encountered. This is in addition to large quantities and maximum output in the shortest possible time. Profimach deep hole drilling machines deliver solutions here that are as precise as they are efficient: Consequently, when through-holes are present – for example, in camshafts and common rails – it is also possible to drill simultaneously from two sides. All over the world, our customers rely here on deep hole drilling machines that have been specially developed for this task with designs that incorporate up to 16 spindles – including fully automated part handling by, for example, synchronized chains, overhead gantries, and robot loading. This allows cycle times that are almost 50 % faster! Profidrill's solutions for automotive industry are designed to work in 24 X 7 mode with minimal downtime combining aspects like close tolerances and high volume production using various types of automation.

Components such as landing gear, turbine shafts, and refuelling pipes, often made of titanium, tempered steels or special alloys such as Inconel, require extremely precise drilling. The material-saving construction processes that are normal in aircraft production also often require deep hole drilling contours for this, with different hole diameters as the drilling depth increases. Profimach deep hole drilling machines of the PDHB series are used for this, which are able to produce all desired internal contours through what is known as bottle boring. Deep Hole Drilling applications for aerospace industry are complex and require super precision output parameters. A combination of multiple processes on same machine are also required. Profidrill machines are designed with all these needs in mind.

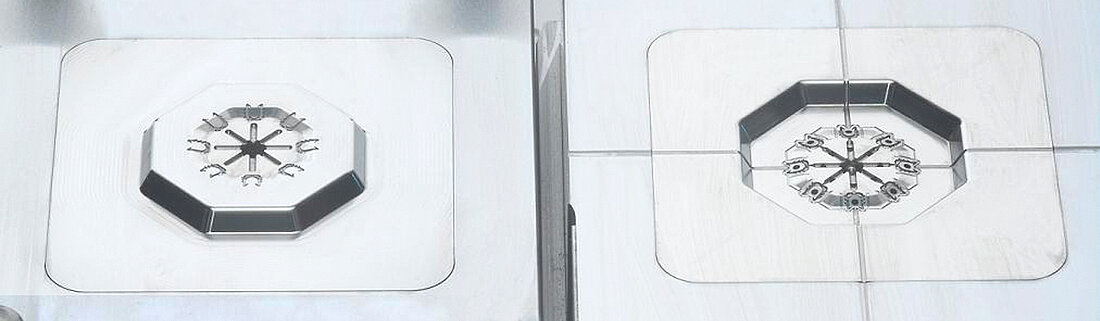

Profimach is raising the competitive bar by lowering the die/mold costs. Having the right machines, with the right technologies specifically suited for complex dies and molds enables you to compete with low-labor-cost countries on the other side of the globe. For some of the most successful die/mold shops, Profimach® innovations in deep hole machining, technology transfer, applications, software and engineering services are key components to helping them compete and win in the new global market. With Profimach®, die/mold shops are able to reduce cycle times and lead-times, lower labor costs through better controlled and unattended machining processes, gain more business by offering high-performance deep hole drilling, all while reducing total investment and operating costs. And with Profimach®’s exclusive Intelligent controls, die/mold shops are able to process big, complex mold program at extremely fast speeds while achieving levels of depth, accuracy and finish of cooling holes previously unobtainable. Precihole’s solutions for the die and mold industry includes innovative and cost-effective solutions for precision manufacturing of mold plates in the fastest possible time with high efficiency. Profidrill’s solutions for the die and mold industry includes innovative and cost-effective solutions for precision manufacturing of mold plates in the fastest possible time with high efficiency.

In earth-moving machines such as dump trucks and dredgers, hydraulic and pneumatic cylinder tubes must work reliably over long periods and under the most difficult conditions. Precise dimensional accuracy and top surface quality on the cylinder tubes are therefore absolutely essential. Besides making precise deep bores in cylinder tubes, Profimach deep hole drilling machines are also suitable for skiving and roller burnishing the drilled tubes (also in double or triple combinations). Automated loading and unloading equipment, as well as automated tool-changing devices, make our PDHB abd PDHG series deep hole drilling machines the ideal solution for economical and precise series production. Profidrill’s Skiving and Roller Burnishing solutions are ideally suited to high volume manufacturing needs of hydraulic cylinder manufacturers while controlling surface finish and wall thickness variation in check.

In the manufacture of ships' rotor shafts in particular but also in the case of numerous components for pumps and powertrains, the field of shipbuilding involves challenging deep hole drilling tasks that can be done with great precision, reliably, and efficiently with Profimach deep hole drilling machines.