PDHB-200-Series Highest flexibility possible

BTA drilling Process: Drilling, Boring and Trepanning

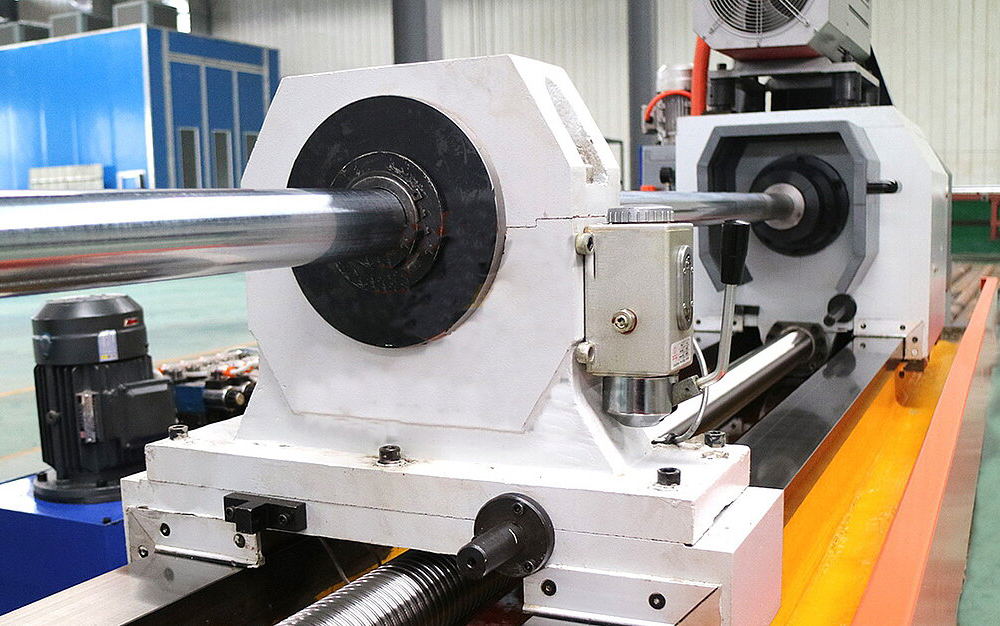

BTA stands for Boring and Trepanning Association which developed this deep hole drilling system. It involves a single drill tube in which high pressure coolant is supplied to the drill through the annular area between the drilled hole and the tube outer diameter. The chips are evacuated through the I.D. of the tube. The drill head is screwed to this drill tube which is much stronger compared to the kidney shaped shank of a gun drill, hence much higher metal removal rates are possible. This involves the use of a Pressure head which is basically a high pressure seal between the workpiece and the drill bush. BTA/STS drilling is generally used for ф19 and above.

Since the chip removal is internal, no v shaped groove is required in the shank, so its cross-section is completely round and this provides more rigidity to the entire system. BTA drilling finds its application in Industries like Oil & Gas, Defence, Steel, Aircraft, Aerospace, Hydraulic Cylinders, and Power etc. For larger diameter deep hole drilling, BTA drilling is the only available option which provides high productivity and precision.

Another system which evolved from BTA single tube system is the Ejector drilling system. It is a system with twin tubes where the coolant is pumped through the space between the inner and outer tube. This eliminates the use of Pressure head and simplifies the system. This was introduced mainly to tool up conventional machines to do Deep hole Drilling.

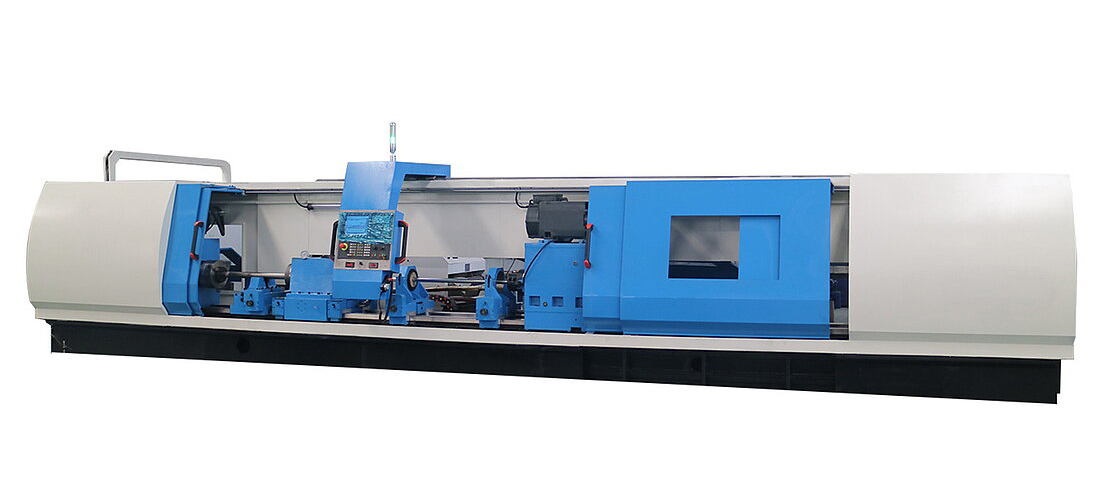

BTA deep hole drilling machine

HEAVY DUTY

BTA deep hole drilling machines PDHB-100 Series

Boring diameter till 100 mmBTA deep hole drilling machines PDHB-160 Series

Boring diameter till 160 mmBTA deep hole drilling machines PDHB-200 Series

Boring diameter till 200 mmBTA deep hole drilling machines PDHB-360 Series

Boring diameter till 360 mm-

BTA deep hole drilling machines PDHB-500 Series

Boring diameter till 500 mm -

BTA deep hole drilling machines PDHB-800 Series

Boring diameter till 800 mm -

BTA deep hole drilling machines PDHB-1000 Series

Boring diameter till 1000 mm -

BTA deep hole drilling machines PDHB-1200 Series

Boring diameter till 1200 mm

Deep hole drilling tools

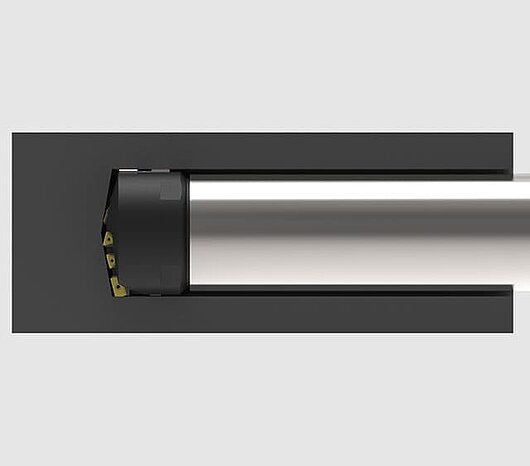

STS System - Single Tube System

Deep Hole Boring Tools

The BTA drill head belongs to internal chip drill head. It consists of a cutter body, a guide key, a blade and a screw(If the hole diameter more than Ø65mm it also includes Support bakelite).

Product description:

The cutter body material is made of high quality steel and is precision heat treated.

Blade and guide key with imported material. (If the hole diameter more than Ø65mm, the Guide key for homemade).

The BTA drill head can process carbon steel, high strength alloy steel, stainless steel and other materials.

It is an alternative to traditional welded drill heads.

Product Advantages:

◆ High processing efficiency

◆ Easy to replace the blade

◆ Low tool consumption