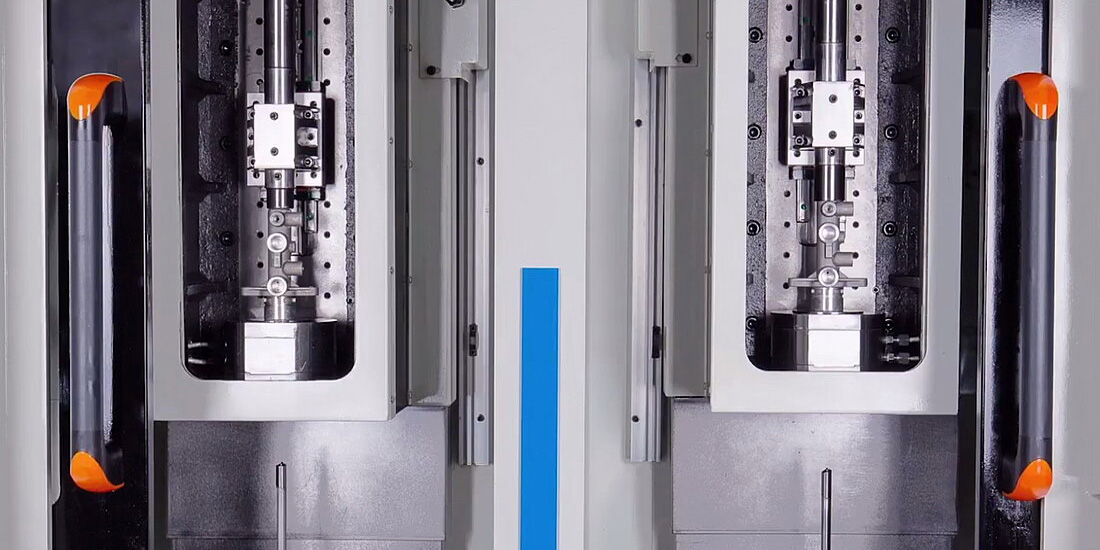

2 Spindle Vertical High Speed Gun Drilling Machine

Twin Spindle Upright High Speed Deep Hole Drilling Machine

Automotive high volume deep hole drilling machines

Deep hole drill PDHVG2-HS Series (two stations)

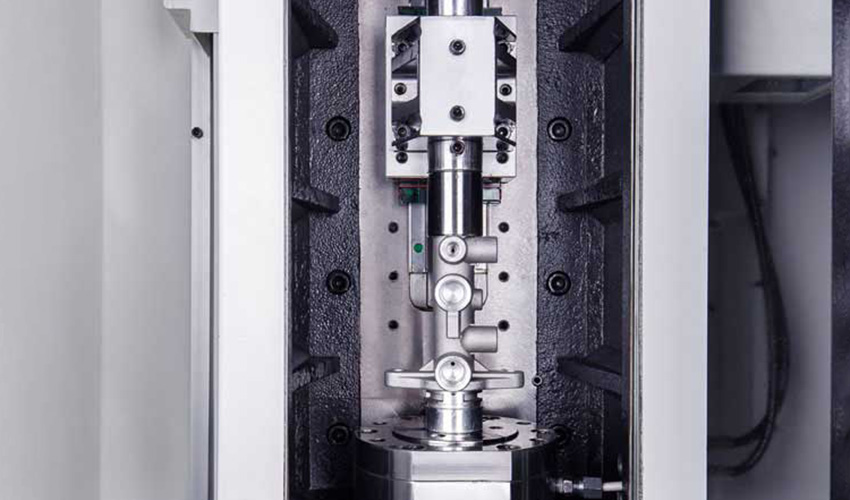

High productive deep hole drilling in shafts, master cylinder and gears

The machine adopts the structure of two-way opposite and simultaneous cutting. Since the two symmetrical holes of the workpiece are processed by two pieces of tools at the same time, the resistance to cutting and the cutting force are in a balanced state. Multiple parts can be processed in series, and the efficiency is more than twice that of a single-piece tool.

This twin spindle high speed deep hole drilling machine is designed and manufactured for making high volume parts like master cylinder, wheel cylinder, clutch cylinder, etc. This deep hole drilling machine is designed with upside down unit spindles. This arrangement allows chips to fall out easily. In addition, twin spindle machine can process two pieces at a time.

PDHVG-HS Series: High speed high volume Deephole drilling machine

High speed drilling for big volume production

| Main parameters | PDHVG2-320HS | PDHVG2-450HS | |

|---|---|---|---|

| Max drilling diameter | mm | ø40 | ø40 |

| Max clamping diameter | mm | ø60 | ø60 |

| Max workpiece length | mm | 320 | 450 |

| Position number | pieces | 2 | 2 |

| Weight | kg | 3700 | 4000 |

| Length × width | mm | 3500×2200 | 3500×2200 |

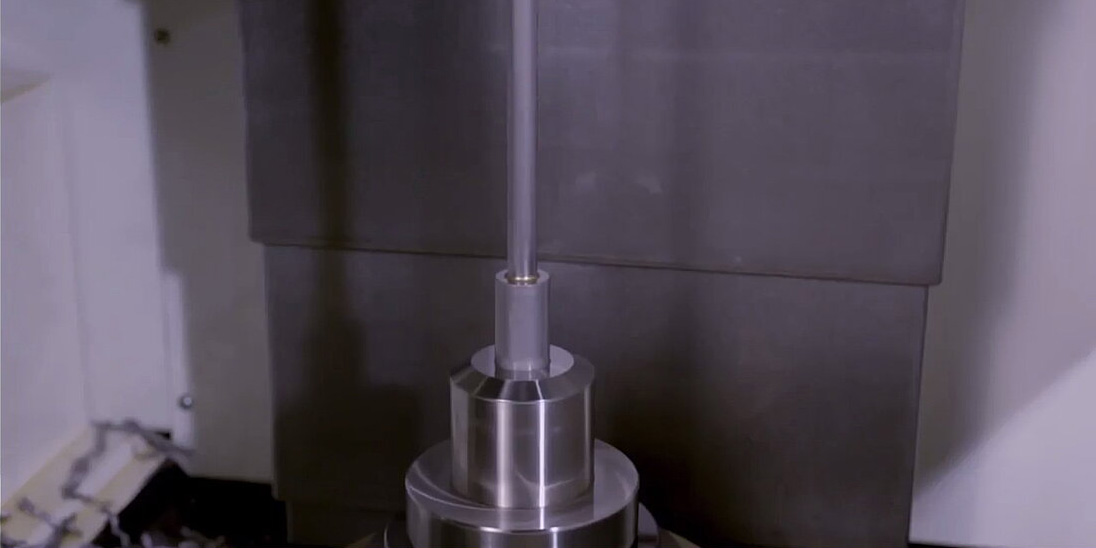

Vertical spindle allows the best chip evacuation available.

Chips fall down by gravity.

High Productivity deep hole drilling Machines

Master brake cylinder before and after deep hole drilling

Welcome to send your message to us