Third Generation SRB - Skiving & Roller Burnishing Machines

We at PRofimach-AiohTec build the best SRB machines in the world

Profimach-AiohTech: Japan High-Tech combined with the european quality design

We build superior quality SRB Machines at most affordable pricing!

For a hydraulic cylinder to operate effectively, precise and uniterupted long time, the cylinder’s ID must be precisely round and have a mirror-like surface finish to ensure a tight seal between the internal diameter wall and the mating internal piston. This is today commonly achieved through skiving and subsequent roller burnishing inside a tubular workpiece. Skiving uses a set of carbide blades positioned around the diameter of a tool to slice away chips and create a geometrically round bore. Roller burnishing, a cold-working process, uses multiple rollers to compress the peaks of material left behind after skiving to generate an extremely smooth surface finish. Burnishing also introduces a residual stress layer into the cylinder wall, which improves cylinder fatigue life.

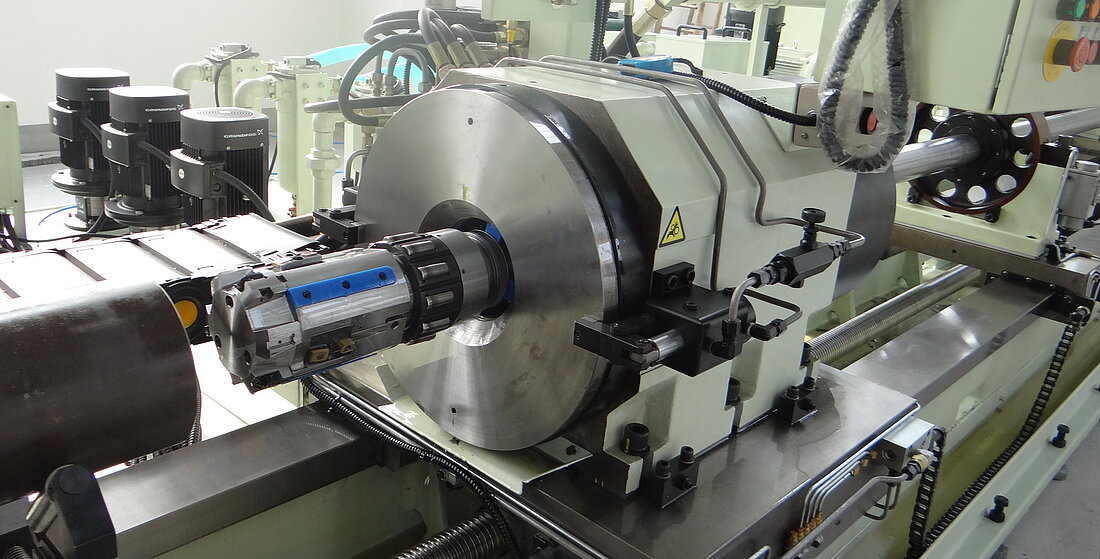

These operations can be performed in one pass using a combination skiving/roller burnishing tool on a BTA-style deep-hole drilling machine. Noting the increasing demand in the hydraulics market for such equipment. We have recently designed our third generation SRB machines, engineered specifically and uniquely to perform skiving and roller burnishing operations, Our new SRB-series machines use a single tool for both operations, achieving roundness tolerances of IT-8 or IT-9 and bore surface finishes as smooth as Ra 0.05 to 0.2 micron in one setup and one tool pass, and this at incredible high speed.

100 % Dedicated SRB Machine!

ONE SPECIFIC TASK: HIGH SPEED, HIGH PRECISION SKIVING AND BURNISHING OF HYDRAULIC TUBES.

Not like others, build-up on the company’s existing BTA drilling machines, 100 percent of our new SRB-series machine is completely new designed in Europe based and with the help and support of the most famous Japanese SRB-Machine maker in the world: Aioh-tech©.

It is engineered to deliver precise tolerances and quality surface finishes. The system may be used for a variety of part types and materials, but more specific high-production, hydraulic cylinder applications.

The system is built for easy setup and operation, fast change-over times and with the system that finishes the internal diameters of workpieces in a single pass, the cycle times can be drastically reduced.

There are three distinct features we took special care that enable our new SRB-series to be highly effective at skiving and roller burnishing:

100 % Dedicated Skiving roller Burnishing Machine!

Workholding

The tubes used for hydraulic cylinders are relatively thin. Care must be taken to secure the tube rigidly enough for the skiving and roller burnishing processes, but not so tightly as to deform it. Therefore, clamping cones are typically used to hold the tubes on both ends instead of three-jaw chucks. This clamping method also facilitates quick workpiece changeovers in automated environments. In addition, extra support must be provided along the length of the tube due to the inherently high length-to-diameter ratio of these workpieces. The new SRB-series uses a differnt types of V-shaped hydraulic clamp to provide this support.

Power train

Thin but wide cuts are taken during skiving. A skiving blade’s radial engagement with the workpiece might be just 0,2 mm and feeds might be 1 mm per revolution, per blade. However, each tool has two or three skiving blades, which multiples the effective feed rate. Similarly, the cold-working roller burnishing process requires a lot of torque and high spindle speed as it plasticizes and compresses the peaks that skiving leaves behind. As a result, the new SRB-series features a more robust power train with higher horsepower motors and faster spindle speeds than conventional BTA drilling machines.others use as base for their machine.

Rotary union

A hydraulic circuit inside the skiving and roller burnishing tool expands the skiving blades and burnishing rollers during cutting operations. Therefore, the new SRB-series has a rotary union at one end of the tool headstock to provide a hydraulic connection throughout the length of the rotating tool. Once the cutting pass is completed, the blades and rollers are retracted into the tool as it is removed from the tube. The tool continues to rotate as it is removed, but nylon guides on the tool and continuous coolant delivery prevent damage to the cylinder wall.

The new SRB-series machines are available in skiving/burnishing diameters ranging from 50 to 850 mm and lengths to 18 meter (larger machines are available upon request). The machines can also be modified to perform optional BTA drilling, counter-boring, and other drilling and tube-finishing operations. In addition, tools can be configured to perform tube finishing on a variety of metals.