Like all tools, gundrills wear out. While a talented operator can still drill a hole with a worn gundrill, it will more often result in a loss of hole tolerance and finish at best. As gundrills wear, they require more thrust and torque while producing more run-out and experiencing greater drift . A dull cutting edge will produce irregular chips, which in turn cause spikes in coolant pressure – sure signs that failure is imminent.

Unlike some tools, gundrills are excellent candidates for resharpening. When performed correctly, the same gundrill can be resharpened to perform as well as a new drill as many as 8 to 10 times. The only visible difference will be seen in the length of solid carbide on the gundrill’s tip.

Even coated drills can be sharpened. Naturally, this will reveal the raw carbide on the face, but this does not impact performance. The coating will remain on the wear pads and continue to improve the gundrill’s size control and ability to leave behind a finished surface. Tool life will be impacted, but the only other option is having it fully resharpened and re-coated by the OEM, which will likely be less cost effective.

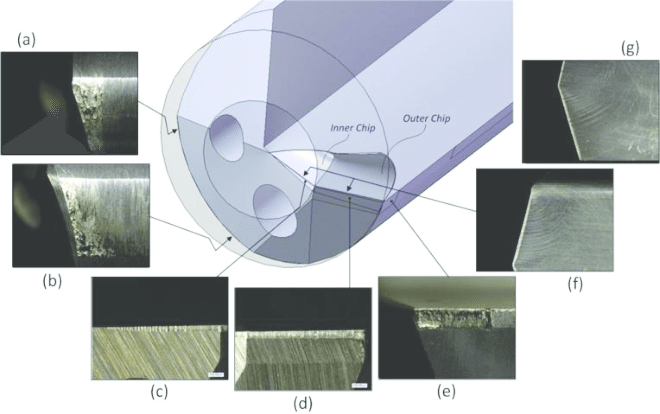

Straightness control in deep hole gundrilling of is challenging. The drills are found to degrade rapidly on the cutting edges, bearing pads and side margins, largely due to the extreme heat resistivity of the high temperature superalloys. Severe adhesive wear developed on the rake and flank faces deteriorates cutting efficiencies of the cutting edges while diffusive wear on the bearing pads and side margins deteriorates self-piloting efficacies of the drill. Coupled with highly irregular wear rates on the inner and outer cutting edges, the drills are forced against the hole at high rotational speeds – leading to escalations in frictional contact, heating and thermal damage on the bearing pads and side margins. As a consequence, the drills are deflected from the designated drilling course and resulted in straightness deviation on the part of hole drilled. Through the accumulation of partial straightness deviation over the course of high aspect ratio drilling, the final hole produced is deflected in a constant trend as governed by the rate and behaviour of tool degradation.

The machine adopts precision rolling track, high-speed motor. The motion is smooth and the friction is small. Grinder can rotate in horizontal and vertical plane. Widely applicable to machine tools with sharpening ATTACHMENT can be accurate and effective grinding a variety of gun drill.

Capacity Ø3-32mm, adopts six-jaw precision chuck, that ensure the center point precision. Six-sided gun drill can be grinded in one clamping, after grinding all six-sided drill lip angles will be completed. Regardless of outer diameter size, the center point accuracy can be guaranteed.

| Gun-Drill Grinding Machine | PGT-250G |

|---|---|

| Table Size | 130*600mm |

| Longitudinal Travel Of The Operating Table | 170mm |

| Horizontal Travel Of The Operating Table | 270mm |

| Elevating Distance Of Wheel Head | 140mm |

| Rotating Angle Of Wheel Head | 360° |

| Wheel Spindle Speeds | 2800rpm |

| Grinding Wheel Size (Ex-DIA*W*Bore –DIA) | Ø125*50*Ø32 |

| Voltage | 220V/ 380V |

| Total Power | 550W |

| Packaging Size(L*W*H) | 760*740*730cm |

| Net/Gross Weight | 145/160kg |

1. The operating table adopts the imported high-precision linear ball slide rail which can ensure the table stable and easy to operate.

2. The machine can be matched with different fittings in lines with tools to grind so as to grind drill bit, screw tap, end-milling cutter. R-shaped turning tool, R-shaped milling cutter, hobbling knife, round paper cutting knife.

3. The motor can rotate 360, The two sides of the motor can be installed with two grinding wheels at the same time. When you grind cutting tools of different materials, you may restart grinding by simply rotating the motor, Which can enhance security and reduce the time of disassembling and reparation.

4. It adopts the FC30 cast iron of high toughness to maintain the precision of the machine.

5. The maximum linear speed of grind wheel is 40m/s.