How Does We Work?

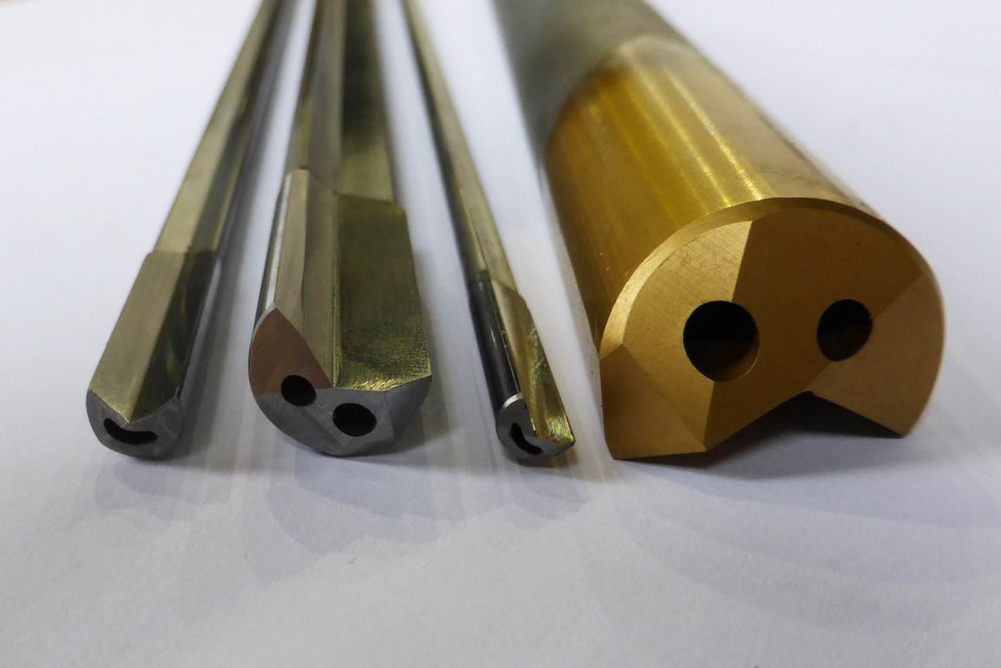

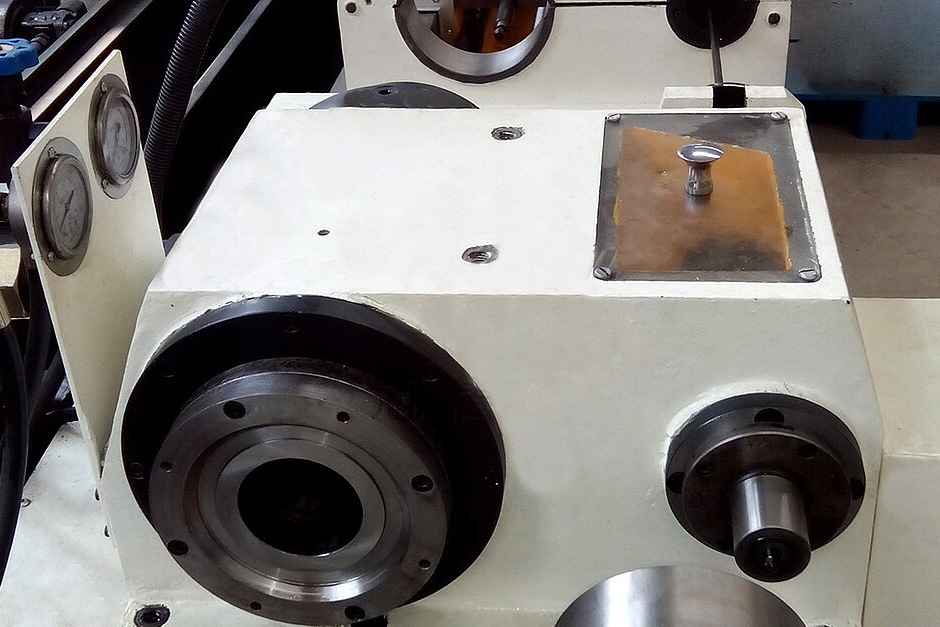

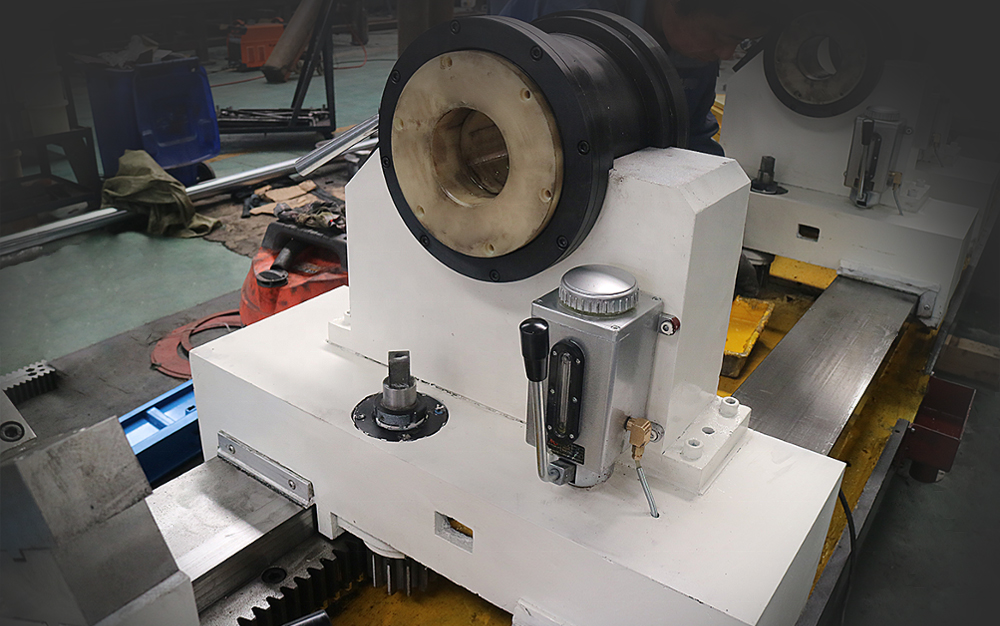

You may come from different industries, but as long as you have a deep hole machine, if you encounter a deep hole processing problems, please contact us freely, we have a professional deep hole processing engineer, who has been solved the deep hole processing problems for many many factories, he has plenty of experiences, and he is the master of deep hole processing and toolings, whatever your problem is, if he comes, see the processing, see the machine, see the toolings, he will find the way. He is the most powerful figure in the deep hole field, he is genius. if you come from abroad, we can go to your company to solve the problem for you.